I/O Systems

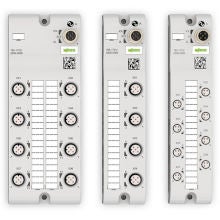

Today I/O Systems take many forms- and all methods are still valid and often combined in a single automation system. As automation technology has advanced, so too has the I/O Systems that bridge the Input / Output (I/O) devices to the automation controller. As revolutionary as PLC's were by replacing rows of relays with rack mounted I/O modules, I/O systems have been undergoing a transformation of its own to decrease wire bundles and move termination points closer to the field devices, and in other forms through digital communications. For smaller PLC's that require some additional I/O, Brick I/O can be added to the existing PLC typically daisy chained via a ribbon cable. As the need to shrink cabinet size by moving the I/O Cable terminations outside the enclosure increased, the first generation of remote sensor termination junction box I/O began. These are mounted in stand-alone junction boxes where one side of the terminal blocks connect via discrete wires to the rack based I/O and the other side connect to the field devices via flexible cables. In an effort to simplify these connections, manufacturers created the On-machine molded junction box I/O that combine multiple signals or ports from a variety of sources into a single cable that connect the control panel terminals and then to the modular I/O. Multiple cordsets connect the junction box ports to the field components, such as sensors or solenoids. The latest trend moves the fieldbus all the way to the field device creating smart components on the network. IO buses like IO-Link and ASI bus provide at the IO feedback providing more information and diagnostics at the device level.